Autotorch Sys 2

Automatic push-button, piezo-electric ignition.

The Autotorch system 2 gives a wide range of interchangeable burners (2102 - 2121) for many uses.

Pressure Equipment Regulations 2016 These torches conform to these regulations.

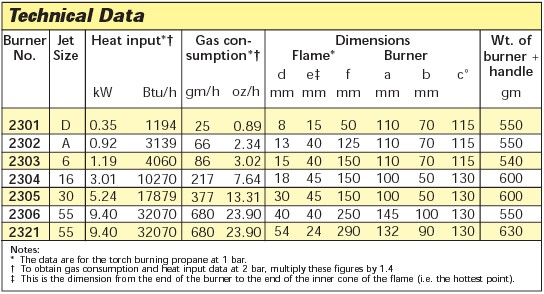

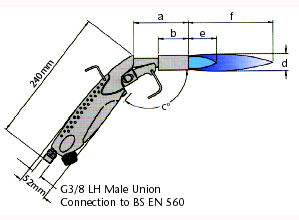

Technical Data - Autotorch System 2

These data are for the 2300 system burners but they are the same for the equivalent burners in the Autotorch System 2 - where for 2102 look at 2302, 2103 look at 2303 etc.

The 2301 and 2101 Burners are no longer available.

Technical Information - Autotorch 2

Gas supply for Autotorch 2100

For use at high pressure (0.35-2bar).

Cylinders

Any standard propane regulator with a screwed connection.

Any of the Tinyregs or Bijou regulators. The No.1051/11 variable Tinyreg for propane is recommended to give the best results from this torch.

Hose

Any of the Tinyregs or Bijou regulators. The No.1051 variable Tinyreg for propane is recommended to give the best results from these torches.

Hose

4.8mm high pressure hose to BS.3212/2 (no.1299) only must be used, with suitable hose clips.

Flashback Arrestors

Flashback arrestors are not needed for these torches

To check the spark

Turn off the gas using the valve with the screw down knob and disconnect the burner. Find a piece of metal to bridge the gap between the burner connection on the handle and the spark point on the hande. Rest the metal on the connection and a few millimetre from the spark point and and push the red button a few times to see if there is a spark. See video by clicking here: Check spark

Use of Torches

General uses of torches

Some of the uses of a Bullfinch torch are:

- Soft and silver soldering

- Central heating installation - capillary joints

- General plumbing work

- Factory maintenance work

- Public utility work

- Telecom work

- Electrical work

- Gas installation

- Tube bending

- Paint stripping

- Modelling

- Jewellery work

- DIY work

- Electrical work with soldering attachment

- Plastic tile laying

- Heat shrinking of sleeves and plastics - e.g. cable jointing for Telecom and electrical installations

- General household jobs

- Removal of fungal growth from beehives

- Other agricultural uses such as removal of feathers from bird carcasses

- Pottery kilns - see below

- Blacksmiths forges

- Glass bead making

- Bitumastic work

- Roof laying

- Torch-on roofing

- Weed burning

- Large pipe work - e.g. weld pre-heating

- Maintenance

- Jewellery

- Refrigeration

- Steam fittings installation

- Model engineering

- Heating and ventilating

- Agricultural machinery maintenance

- General engineering repair

- Appliance repair

- Lighting barbecues

- Lighting braziers, coal and coke fires

- Technoweld aluminium brazing

And for larger burners in Standard blowtorch range:

Uses of Autotorch brazing system

In addition to the uses shown which these brazing burners will usually do faster, the brazing system is ideal for silver soldering of copper pipes and as a portable bronze brazing system for the following areas of work:

The Autotorch acetylene system

Has improved performance over the Autotorch brazing system and is particularly good for Bronze brazing and Technoweld work.

Kilns

Bullfinch standard burners can be used for providing the burners for kilns. Most kilns have different requirements and so it is hard to give specific advice. We do have an informal information sheet on how our burners may be set up for a kiln - see downloads section. It is important to remember that the burners do require space round them to allow air to be drawn in for combustion at the front and the back of the burners.

Flame Temperatures

Technical information: flames

Although the flame temperature of an LPG (propane or butane) air burner at the hottest point is approximately 1900oC, the actual temperature a heated component can attain is much lower than this and depends on the burner, and the thermal properties of the component and its surroundings.

Acetylene-air and MAP//Pro gas-air will give flame temperatures 200-300oC above this and component temperatures 200-300oC higher too.

The Autotorch brazing burners can give temperatures up to 950oC under general conditions and up to 1200oC in ideal conditions only. They can therefore bronze braze under most conditions as well as being able to make faster soft and silver soldered joints. They are particularly good for hard/silver soldering of copper pipes.

The Autotorch 2300 series burners, the Autotorch System 2 burners and the Standard torch burners can give temperatures up to 800oC under general conditions. They are, therefore, ideal for soft and silver soldering and lead welding, but cannot be used for bronze brazing.

The Autotorch acetylene burners can give temperatures up to 1100oC undergeneral conditions and 1350oC under ideal conditions and can be used to do bronze brazing as well as the other general uses of torches discussed above.

MAP//Pro gas used on the FirePower, AutoPerformer and Performer torches will generally achieve temperatures between the Autotorch brazing burners and the Autotorch acetylene burners.