Safety & Technical

Safety Checks - Hose/regulator life

Safety Checks

With regard to safety checks for our equipment we would recommend a comprehensive check as follows when the equipment has not been used for sometime and regular checks as follows:

- regularly check by smell and leak detecting fluid that there are no leaks of gas

- regularly check that the appliance is working correctly and the flames are burning correctly (usually an almost colourless blue flame) and there are no signs of overheating in the appliance or damage to the appliance

- regularly check that any lpg hose is clean and free from undue wear and cracking and is properly attached to the regulator and the appliance with hose clips or ferrules

- when replacing the gas cylinder ensure that the new cylinder has a clean and undamaged connection and the regulator connection is clean and undamaged

- please consult the instructions for the appliance for more specific checks and instructions - these can be obtained online for most appliances

- the Bullfinch Safety Precautions give guidance for the use of many lpg appliances

- the equipment should not be used if you are concerned over any of these aspects. Please then consult your dealer or manufacturer

Hose Life

With regard to hose life we issue the following recommendation:

Our hose is made in accordance with BS3212/2.

Storage - see BS ISO 2230. Hose generally has a shelf life of 7 years as long as it is stored at reasonable temperatures in dry conditions away from direct sunlight. This life can be extended by another 3 years if it is examined and tested and proved to be in good condition.

Service life - From the date the hose is first used we would recommend it is replaced after a further 5 years and that it is examined regularly for signs of cracks or wear or gas leakage and is replaced if it is not in good condition. Generally discolouration due to sunlight is not harmful as long as there are no signs of cracking.

Regulator Life

Conformity to Regulations and CE Marking

Gas Appliances Regulations 2018

It is a legal requirement that many gas appliances offered for sale conform to the Gas Appliances Regulations 2018 (which come from the European Gas Appliances Regulations EU 2016/426). These are generally appliances that are used to heat people, cook or provide lighting. They have to be independently certified by ‘Notified Bodies’ and have to carry the CE mark to show that they conform to the regulations. In addition a Notified body has to carry out surveillance of the production of these appliances.

The Bullfinch brand appliances certified are: Radiant heater No. 2200, Industrial space heater No. 1400, and other products certified are Cabinet heaters 7098, 7099, and Marquee heaters 2208 and 2217 and Master Heaters, and boiling rings etc. All other Bullfinch brand appliances and equipment are exempt.

Blowtorches, furnaces and Decorative flame appliances such as Event torches, beacons etc do not fall under the Regulations and are not required to be CE marked.

Essential requirements We take safety and performance of appliances very seriously and where Gas Appliances doe not require CE marking they conform to the Essential Requirements of these regulations and other European and applicable standards. They also meet the essential requirements of the Pressure Equipment Regulations - see below.

Construction Products Regulations 2011

None of our products come under these regulations and so do not need to be CE marked for them - many are CE marked under the Gas Appliances Regulations - see above.

Pressure Equipment Regulations 2016

Products operating on gas pressures above 0.5 bar are required to meet these regulations. In the case of appliances made and sold by Bullfinch this means they have to meet sound engineering practices and we can make a declaration that they do.

Flashback arrestors

Please note that Flashback arrestors are not needed when propane or butane is used with air. This is true for Bullfinch propane or butane burning appliances. Flashback arrestors are required for the Bullfinch Autotorch for acetylene and for oxy-propane and oxy-acetylene systems.

Download letter from HSE for verification

COSHH and RoHS and REACH

Our products conform to these regulations and we require our suppliers to ensure that their products conform to them

Conflict Free Minerals Policy

BULLFINCH GAS EQUIPMENT LTD will not knowingly procure material supplies and components that contain minerals that directly or indirectly finance or benefit armed groups in the Democratic Republic of Congo (DRC) or an adjoining country. We stipulate that our suppliers must support this policy in their own procurement guidelines for their supply chain.

Modern Slavery Act 2015

BULLFINCH GAS EQUIPMENT LTD comply with the provisions of this act to prevent the use of slavery, servitude and forced or compulsory labour and human trafficking in our workforce. We stipulate that our suppliers must conform to this act and ensure that those in their supply chain also conform to the act.

Low Pressure Appliances

Traditionally most low pressure appliances in UK operate at 28/29 mbar with butane and 37 mbar with propane. This is category I3+. General portable appliances like patio heaters, barbecues, boiling rings, hotplates will operate off either supply but care needs to be taken to read the instructions as there may be some variation in this.

New caravans and some other environments now have to be supplied with special regulators that are rated at 30mbar whether propane or butane is used. This is category I3B/P. Built in appliances will be made for this pressure and they may not work satisfactorily on a I3+ supply. Portable appliances will generally work satisfactorily off this supply for example using our Gas/barbecue point no. 6087/01.

Gas Supply Information

Low pressure appliances - Type I3+ - requirements for gas supply. Where type I3+ low pressure appliances are referred to (butane at 28/29mbar or propane at 37 mbar), the following hoses, clips and regulators are suitable:

- Regulator

- No. 7026 for a butane cylinder with a 20mm clip on connection - 28 mbar or

- No. 7027 for a butane cylinder with a 21mm clip on connection - 28 mbar or

- No. 330 for a propane cylinder with a POL connection - 37 mbar or

- No. 7069 for a propane cylinder with a 27mm clip on connection - 37 mbar (eg Calor Patio Gas, or Flogas Leisure Propane Gas)

- No. 1314 or No.1319 - Hose - we would suggest at least 3m of 8mm bore hose

- No. 1306 Hose clips - 2 off

These products can also generally be used off a I3B/P supply which is propane or butane at 30mbar pressure. This is the supply in new caravans and in some other environments and means that they can be used from a Gas/Barbecue point - our No. 6087/01.

Always check the manufacturers' instructions before using any appliance.

LP Gas and Equipment association

Member of Liquid Gas UK (previously UKLPG, LPGA and ALGED) where you can get technical and safety advice.

There is a comprehensive set of industry recognised Codes of Practice available.

For information on LPG Applications see:

Exceptional Energy in Action - the LPG Applications Website www.lpg-apps.org

Flash Back Arrestors

Flashback arrestors

Please note that Flashback arrestors are not needed when propane or butane is used with air. This is true for Bullfinch propane or butane burning appliances. Flashback arrestors are required for the Bullfinch Autotorch for acetylene and for oxy-propane and oxy-acetylene systems.

Download email from HSE for verification

.

Safety Information Leaflet

Gives much of the information in this section on one leaflet. Ideal for all users of LPG - dealers, customers, users, students etc. Contact us for copies or you can download in 2 parts.

Safety Leaflet Part 1 (PDF) | Safety Leaflet Part 2 (PDF)

Public/Products/Employers Liability Insurance

We carry £10 million of public and products liability and employers liability insurance

Expires - 30th June 2026

Quality Management System

Bullfinch systems controlling quality have been certified as meeting the International Quality Standard BS EN ISO 9001:2015.

Download Certificate

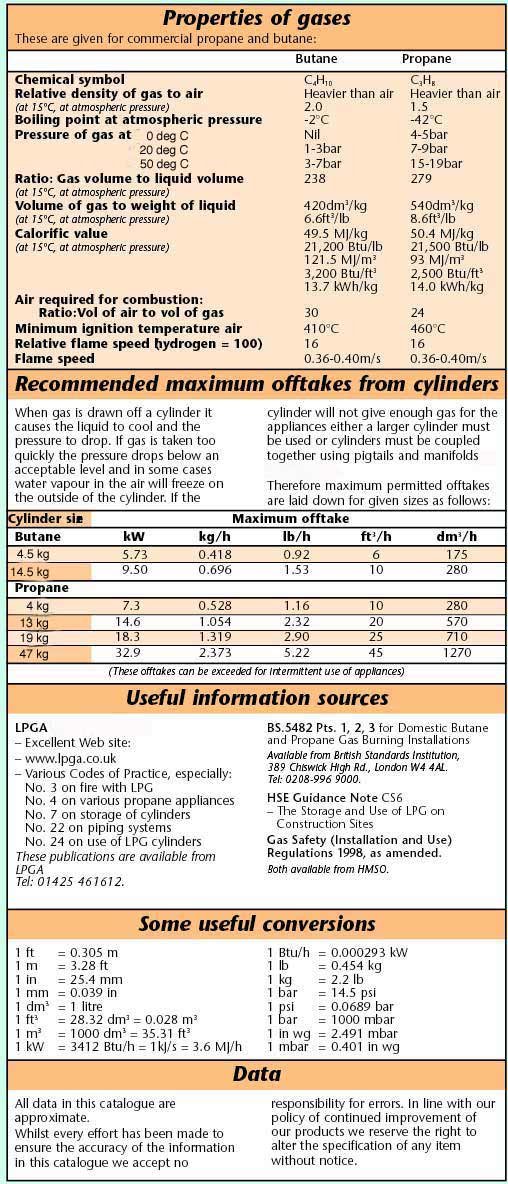

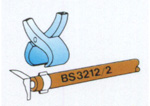

Properties of gases and other information

Safety Precautions & Ventilation Requirements

Bullfinch appliances and equipment have all been especially designed for use with Liquefied Petroleum Gases (propane and butane) and will give long and reliable service to the user provided they are correctly operated and maintained.

It is, however, essential that sensible safety precautions be followed with any appliances using butane and propane gases which are considerably heavier than air and highly inflammable; and because of these facts, we list here simple safety measures which should always be adopted when using the appliances. Failure to observe these could result in a serious accident.

Personnel

Ensure that you know how to operate the equipment and never allow anyone other than a competent person to connect or disconnect appliances and regulators.

Appliances

Read the instructions provided with the appliance, taking particular care to ensure that the gas type is correct and the supply can provide sufficient gas for the appliance and any other appliances drawing on the same supply. Ensure that the regulator provides gas at the correct pressure. Site the appliance so that it cannot overheat any surfaces and cannot cause an accident. The appliance should burn cleanly without the formation of soot. If it does not, turn it off and ensure the maintenance is carried out by a competent person before re-using.

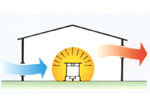

VentilationAll LPG equipment consumes oxygen and emits carbon dioxide in use so that when using unflued equipment in a confined space it is important that there is ADEQUATE PERMANENT VENTILATION & ADEQUATE FREE SPACE surrounding it. These requirements are laid down in various British Standard Codes of Practice and a summary of the main requirements is given below. |

|

CylindersMake sure the cylinder is large enough for your requirements. Cylinders must be sited away from any heat source, in a well ventilated place wherever possible and must stand in a stable upright position. Never put a cylinder in a sewer, culvert or work hole. Propane cylinders should not be stored indoors. Don’t use Propane cylinders indoors except when necessary for work processes and/or for short |

|

RegulatorsBullfinch appliances should only be used in conjunction with a British Standard regulator. It is important to check that the regulator; a) gives the correct pressure for the appliance, b) is suitable for the gas being used (check also that the gas is suitable for the appliance), c) has a large enough maximum flow for the appliance. For propane cylinders, and for butane cylinders having screwed connectors: Always, before connecting a regulator to a cylinder, ensure that the mating parts are clean, free from dirt and undamaged, and, in the case of butane regulators, check that the washer is in place on the spigot of the connector and is in good condition. The connecting nut of the regulator must be spanner tightened to the cylinder valve. (Note: The thread is left-handed.) For butane cylinders with ‘switch-on’ or ‘clip-on’ connectors: Consult your dealer on the type of adaptor or regulator you require and fit in accordance with the manufacturer’s instructions. |

|

Screwed connectionsMost screwed connections should be firmly tightened with a spanner. Note that all nuts with notches on the hexagon have a left-handed thread. |

|

Hose and clipsBritish Standard hose only must be used for passing these gases and it must be securely attached with hose clips to the ends provided. Low pressure hose, (which must show the number BS.3212/1) must only be used for pressures up to 50mbar. High pressure hose (which must show the number BS.3212/2) can be used for all pressure up to 17.5 bar. Hose and clips should be regularly inspected and replaced if worn or damaged. |

|

LeaksAfter connecting appliances/regulators, etc., check that there is no leak of gas before using. Propane and butane have a distinctive smell and a leak can usually be detected immediately by this fact. If a leak is suspected, extinguish all naked lights and close the cylinder valve. NEVER look for a leak with a naked flame, but trace it by smell and confirm by brushing leak-detecting fluid (or soapy water) over the suspected joint. Equipment must not be used until any leak is eliminated. |

|

FireIf a fire develops, try to turn off the cylinder valve, remove the cylinder from the fire and extinguish the fire with a dry compound extinguisher. (Do not use a water jet on a fire of liquid LPG). If this is too dangerous call the fire brigade and move all people from the area. |

|

Turning offAfter using a portable appliance it is IMPORTANT a) that the cylinder valve is closed first thus allowing the gas in the system to burn off: b) that any valve fitted to the appliance is then closed to ensure that when the appliance is again used the turning on of the cylinder valve does not allow gas to escape from the appliance before being lighted. |

|

ProblemsIf you are in any doubt about the operation of the appliance please consult your dealer, or contact us directly. |

|

Ventilation Requirements

For the use of unflued appliances in a confined space. These are general requirements - those for specific appliances may vary from these - see appliance instructions.

Main requirements

- The volume of the room space in which an appliance is used must be at least 10m3 for each 1kW of continuous heat input with a minimum room size of 15m3. This is in addition to the volume required for other appliances.

- Permanent ventilation must be provided by at least 25cm2 of free ventilation area for each kW of continuous heat input. This is in addition to that required for other appliances and the occupants, and there must be a minimum of 50cm2 of free ventilation area. The ventilation area must be divided between high and low level, and the ventilators must be constructed so that they cannot be closed. If the space is to be used for sleeping, the appliances must be turned off before retiring.