Safety Checks

With regard to safety checks for our equipment we would recommend a comprehensive check as follows when the equipment has not been used for sometime and regular checks as follows:

- regularly check by smell and leak detecting fluid that there are no leaks of gas

- regularly check that the appliance is working correctly and the flames are burning correctly (usually an almost colourless blue flame) and there are no signs of overheating in the appliance or damage to the appliance

- regularly check that any lpg hose is clean and free from undue wear and cracking and is properly attached to the regulator and the appliance with hose clips or ferrules

- when replacing the gas cylinder ensure that the new cylinder has a clean and undamaged connection and the regulator connection is clean and undamaged

- please consult the instructions for the appliance for more specific checks and instructions - these can be obtained online for most appliances

- the Bullfinch Safety Precautions give guidance for the use of many lpg appliances

- the equipment should not be used if you are concerned over any of these aspects. Please then consult your dealer or manufacturer

Hose Life

With regard to hose life we issue the following recommendation:

Our hose is made in accordance with BS3212/2.

Storage - see BS ISO 2230. Hose generally has a shelf life of 7 years as long as it is stored at reasonable temperatures in dry conditions away from direct sunlight. This life can be extended by another 3 years if it is examined and tested and proved to be in good condition.

Service life - From the date the hose is first used we would recommend it is replaced after a further 5 years and that it is examined regularly for signs of cracks or wear or gas leakage and is replaced if it is not in good condition. Generally discolouration due to sunlight is not harmful as long as there are no signs of cracking.

Regulator Life

Storage - a regulator should be stored at reasonable temperatures in dry conditions.

Service life It is recommended that regulators should be replaced after 10 years from the time of first use. But a regulator should be regularly checked for damage or incorrect performance and replaced if not in good condition.

Carbon Monixide Detectors We would recommend the use of carbon monoxide detectors where the heaters are used in confined spaces.

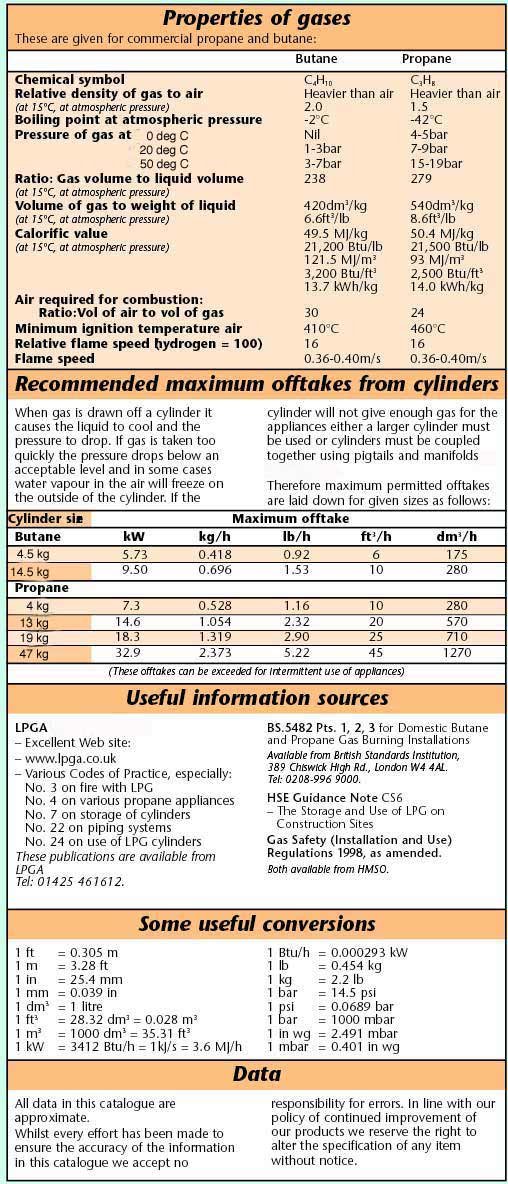

Traditionally most low pressure appliances in UK operate at 28/29 mbar with butane and 37 mbar with propane. This is category I3+. General portable appliances like patio heaters, barbecues, boiling rings, hotplates will operate off either supply but care needs to be taken to read the instructions as there may be some variation in this.

New caravans and some other environments now have to be supplied with special regulators that are rated at 30mbar whether propane or butane is used. This is category I3B/P. Built in appliances will be made for this pressure and they may not work satisfactorily on a I3+ supply. Portable appliances will generally work satisfactorily off this supply for example using our Gas/barbecue point no. 6087/01.

Gas Supply Information

Low pressure appliances - Type I3+ - requirements for gas supply. Where type I3+ low pressure appliances are referred to (butane at 28/29mbar or propane at 37 mbar), the following hoses, clips and regulators are suitable:

- Regulator

- No. 7026 for a butane cylinder with a 20mm clip on connection - 28 mbar or

- No. 7027 for a butane cylinder with a 21mm clip on connection - 28 mbar or

- No. 330 for a propane cylinder with a POL connection - 37 mbar or

- No. 7069 for a propane cylinder with a 27mm clip on connection - 37 mbar (eg Calor

Patio Gas, or Flogas Leisure Propane Gas)

- No. 1314 or No.1319 - Hose - we would suggest at least 3m of 8mm bore hose

- No. 1306 Hose clips - 2 off

These products can also generally be used off a I3B/P supply which is propane or butane at 30mbar pressure. This is the supply in new caravans and in some other environments and means that they can be used from a Gas/Barbecue point - our No. 6087/01.

Always check the manufacturers' instructions before using any appliance.

Gas Appliances Regulations 2018

It is a legal requirement that many gas appliances offered for sale conform to the Gas Appliances Regulations 2018 (which come from the European Gas Appliances Regulations EU 2016/426). These are generally appliances that are used to heat people, cook or provide lighting. They have to be independently certified by ‘Notified Bodies’ and have to carry the CE mark to show that they conform to the regulations. In addition a Notified body has to carry out surveillance of the production of these appliances.

The Bullfinch brand appliances certified are: Radiant heater No. 2200, Industrial space heater No. 1400, and other products certified are Cabinet heaters 7098, 7099, and Marquee heaters 2208 and 2217 and Master Heaters, and boiling rings etc. All other Bullfinch brand appliances and equipment are exempt.

Blowtorches, furnaces and Decorative flame appliances such as Event torches, beacons etc do not fall under the Regulations and are not required to be CE marked.

Essential requirements We take safety and performance of appliances very seriously and where Gas Appliances doe not require CE marking they conform to the Essential Requirements of these regulations and other European and applicable standards. They also meet the essential requirements of the Pressure Equipment Regulations - see below.

Construction Products Regulations 2011

None of our products come under these regulations and so do not need to be CE marked for them - many are CE marked under the Gas Appliances Regulations - see above.

Pressure Equipment Regulations 2016

Products operating on gas pressures above 0.5 bar are required to meet these regulations. In the case of appliances made and sold by Bullfinch this means they have to meet sound engineering practices and we can make a declaration that they do.

Flashback arrestors

Please note that Flashback arrestors are not needed when propane or butane is used with air. This is true for Bullfinch propane or butane burning appliances. Flashback arrestors are required for the Bullfinch Autotorch for acetylene and for oxy-propane and oxy-acetylene systems.

Download letter from HSE for verification

COSHH and RoHS and REACH

Our products conform to these regulations and we require our suppliers to ensure that their products conform to them

Conflict Free Minerals Policy

BULLFINCH GAS EQUIPMENT LTD will not knowingly procure material supplies and components that contain minerals that directly or indirectly finance or benefit armed groups in the Democratic Republic of Congo (DRC) or an adjoining country. We stipulate that our suppliers must support this policy in their own procurement guidelines for their supply chain.

Modern Slavery Act 2015

BULLFINCH GAS EQUIPMENT LTD comply with the provisions of this act to prevent the use of slavery, servitude and forced or compulsory labour and human trafficking in our workforce. We stipulate that our suppliers must conform to this act and ensure that those in their supply chain also conform to the act.

Flashback arrestors

Please note that Flashback arrestors are not needed when propane or butane is used with air. This is true for Bullfinch propane or butane burning appliances. Flashback arrestors are required for the Bullfinch Autotorch for acetylene and for oxy-propane and oxy-acetylene systems.

Download email from HSE for verification

.

Member of Liquid Gas UK (previously UKLPG, LPGA and ALGED) where you can get technical and safety advice.

There is a comprehensive set of industry recognised Codes of Practice available.

For information on LPG Applications see:

Exceptional Energy in Action - the LPG Applications Website www.lpg-apps.org

Gives much of the information in this section on one leaflet. Ideal for all users of LPG - dealers, customers, users, students etc. Contact us for copies or you can download in 2 parts.

Safety Leaflet Part 1 (PDF) | Safety Leaflet Part 2 (PDF)

We carry £10 million of public and products liability and employers liability insurance

Expires - 30th June 2026

Click here to download insurance details

Bullfinch systems controlling quality have been certified as meeting the International Quality Standard BS EN ISO 9001:2015.

Download Certificate

Technical information: flames

Although the flame temperature of an LPG (propane or butane) air burner at the hottest point is approximately 1900oC, the actual temperature a heated component can attain is much lower than this and depends on the burner, and the thermal properties of the component and its surroundings.

Acetylene-air and MAP//Pro gas-air will give flame temperatures 200-300oC above this and component temperatures 200-300oC higher too.

The Autotorch brazing burners can give temperatures up to 950oC under general conditions and up to 1200oC in ideal conditions only. They can therefore bronze braze under most conditions as well as being able to make faster soft and silver soldered joints. They are particularly good for hard/silver soldering of copper pipes.

The Autotorch 2300 series burners, the Autotorch System 2 burners and the Standard torch burners can give temperatures up to 800oC under general conditions. They are, therefore, ideal for soft and silver soldering and lead welding, but cannot be used for bronze brazing.

The Autotorch acetylene burners can give temperatures up to 1100oC undergeneral conditions and 1350oC under ideal conditions and can be used to do bronze brazing as well as the other general uses of torches discussed above.

MAP//Pro gas used on the FirePower, AutoPerformer and Performer torches will generally achieve temperatures between the Autotorch brazing burners and the Autotorch acetylene burners.