Blowtorches & Gas

Copper is 1st Choice for UK contactors for plumbing pipework and Bullfinch blowtorches are ideal for this.

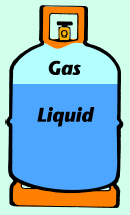

Typical layout for a torch being used on propane gas:

- a burner,

- the torch handle,

- a length of hose secured by

- two hose clips

- a regulator.

The regulator keeps the gas pressure constant so that the torch works well in all circumstances. This connects to the cylinder of propane with a screwed connection.

The burner size varies depending on the job to be done and most Bullfinch torches have interchangeable burners.

The Performer and FirePower ranges fit straight onto the small cylinders and so the hose and separate regulators are not required.

The Torch Kits shown in most sections are ready for use - all you need is a suitable cylinder of propane with screwed connections - butane cylinders now only have clip on connections and high pressure regulators are not available for these systems.

Torch Poster can supply as A4 or A2 sizes Download poster of torches ranges

Our torches are made to BS EN 9012:2011

Pressure Equipment Regulations 2016 All our torches conform to these regulations.

Please note that Flashback arrestors are not needed when propane or butane is used with air. This is true for Bullfinch propane or butane burning appliances including these lpg (propane and butane) burning torches.

Flashback arrestors are required for the Bullfinch Autotorch for acetylene and for oxy-propane and oxy-acetylene systems. Download email from HSE for verification.

For a Hot air blow torch for heat shrink and some economy torches see the Bullfinch Extra Range

Flames Temperatures

Technical information: flames

Although the flame temperature of an LPG (propane or butane) air burner at the hottest point is approximately 1900oC, the actual temperature a heated component can attain is much lower than this and depends on the burner, and the thermal properties of the component and its surroundings.

Acetylene-air and MAP//Pro gas-air will give flame temperatures 200-300oC above this and component temperatures 200-300oC higher too.

The Autotorch brazing burners can give temperatures up to 950oC under general conditions and up to 1200oC in ideal conditions only. They can therefore bronze braze under most conditions as well as being able to make faster soft and silver soldered joints. They are particularly good for hard/silver soldering of copper pipes.

The Autotorch 2300 series burners, the Autotorch System 2 burners and the Standard torch burners can give temperatures up to 800oC under general conditions. They are, therefore, ideal for soft and silver soldering and lead welding, but cannot be used for bronze brazing.

The Autotorch acetylene burners can give temperatures up to 1100oC undergeneral conditions and 1350oC under ideal conditions and can be used to do bronze brazing as well as the other general uses of torches discussed above.

MAP//Pro gas used on the FirePower, AutoPerformer and Performer torches will generally achieve temperatures between the Autotorch brazing burners and the Autotorch acetylene burners.

Use of Torches

General uses of torches

Some of the uses of a Bullfinch torch are:

- Soft and silver soldering

- Central heating installation - capillary joints

- General plumbing work

- Factory maintenance work

- Public utility work

- Telecom work

- Electrical work

- Gas installation

- Tube bending

- Paint stripping

- Modelling

- Jewellery work

- DIY work

- Electrical work with soldering attachment

- Plastic tile laying

- Heat shrinking of sleeves and plastics - e.g. cable jointing for Telecom and electrical installations

- General household jobs

- Removal of fungal growth from beehives

- Other agricultural uses such as removal of feathers from bird carcasses

- Pottery kilns - see below

- Blacksmiths forges

- Bitumastic work

- Roof laying

- Torch-on roofing

- Weed burning

- Large pipe work - e.g. weld pre-heating

- Maintenance

- Jewellery

- Refrigeration

- Steam fittings installation

- Model engineering

- Heating and ventilating

- Agricultural machinery maintenance

- General engineering repair

- Appliance repair

- Lighting barbecues

- Lighting braziers, coal and coke fires

- Technoweld aluminium brazing

And for larger burners in Standard blowtorch range:

Uses of Autotorch brazing system

In addition to the uses shown which these brazing burners will usually do faster, the brazing system is ideal for silver soldering of copper pipes and as a portable bronze brazing system for the following areas of work:

The Autotorch acetylene system

Has improved performance over the Autotorch brazing system and is particularly good for Bronze brazing and Technoweld work.

Kilns

Bullfinch standard burners can be used for providing the burners for kilns. Most kilns have different requirements and so it is hard to give specific advice. We do have an informal information sheet on how our burners may be set up for a kiln - see downloads section. It is important to remember that the burners do require space round them to allow air to be drawn in for combustion at the front and the back of the burners.

Use of Torches

General uses of torches

Some of the uses of a Bullfinch torch are:

- Soft and silver soldering

- Central heating installation - capillary joints

- General plumbing work

- Factory maintenance work

- Public utility work

- Telecom work

- Electrical work

- Gas installation

- Tube bending

- Paint stripping

- Modelling

- Jewellery work

- DIY work

- Electrical work with soldering attachment

- Plastic tile laying

- Heat shrinking of sleeves and plastics - e.g. cable jointing for Telecom and electrical installations

- General household jobs

- Removal of fungal growth from beehives

- Other agricultural uses such as removal of feathers from bird carcasses

- Pottery kilns - see below

- Blacksmiths forges

- Bitumastic work

- Roof laying

- Torch-on roofing

- Weed burning

- Large pipe work - e.g. weld pre-heating

- Glass bead making

- Maintenance

- Jewellery

- Refrigeration

- Steam fittings installation

- Model engineering

- Heating and ventilating

- Agricultural machinery maintenance

- General engineering repair

- Appliance repair

- Lighting barbecues

- Lighting braziers, coal and coke fires

- Technoweld aluminium brazing

And for larger burners in Standard blowtorch range:

Uses of Autotorch brazing system

In addition to the uses shown which these brazing burners will usually do faster, the brazing system is ideal for silver soldering of copper pipes and as a portable bronze brazing system for the following areas of work:

The Autotorch acetylene system

Has improved performance over the Autotorch brazing system and is particularly good for Bronze brazing and Technoweld work.

Kilns

Bullfinch standard burners can be used for providing the burners for kilns. Most kilns have different requirements and so it is hard to give specific advice. We do have an informal information sheet on how our burners may be set up for a kiln - see downloads section. It is important to remember that the burners do require space round them to allow air to be drawn in for combustion at the front and the back of the burners.

Flame Temperatures

Technical information: flames

Although the flame temperature of an LPG (propane or butane) air burner at the hottest point is approximately 1900oC, the actual temperature a heated component can attain is much lower than this and depends on the burner, and the thermal properties of the component and its surroundings.

Acetylene-air and MAP//Pro gas-air will give flame temperatures 200-300oC above this and component temperatures 200-300oC higher too.

The Autotorch brazing burners can give temperatures up to 950oC under general conditions and up to 1200oC in ideal conditions only. They can therefore bronze braze under most conditions as well as being able to make faster soft and silver soldered joints. They are particularly good for hard/silver soldering of copper pipes.

The Autotorch 2300 series burners, the Autotorch System 2 burners and the Standard torch burners can give temperatures up to 800oC under general conditions. They are, therefore, ideal for soft and silver soldering and lead welding, but cannot be used for bronze brazing.

The Autotorch acetylene burners can give temperatures up to 1100oC undergeneral conditions and 1350oC under ideal conditions and can be used to do bronze brazing as well as the other general uses of torches discussed above.

MAP//Pro gas used on the FirePower, AutoPerformer and Performer torches will generally achieve temperatures between the Autotorch brazing burners and the Autotorch acetylene burners.

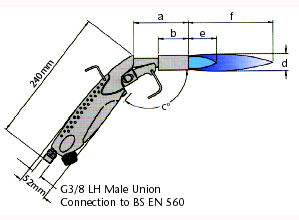

Technical Information - Autotorch 2300

Gas supply for Autotorch 2300 and System 2 - 2100

For use at high pressure (0.35-2bar).

Cylinders

Any standard propane regulator with a screwed connection.

Any of the Tinyregs or Bijou regulators. The No.1051/11 variable Tinyreg for propane is recommended to give the best results from this torch.

Hose

4.8mm high pressure hose to BS.3212/2 (no.1299) only must be used, with suitable hose clips. The Handle 2300 and the Tinyreg 1051/11 require Hose connectors 1021 to fit to the hose.

The hose assembly 1441 is ideal for connecting the Handle 2300 to a Variable Tinyreg 1051/11 - hose connectors included.

Flashback arrestors are not needed for these torches (download letter from HSE for verification).

To check the spark

Turn off the gas using the valve with the screw down knob and disconnect the burner. Find a piece of metal to bridge the gap between the burner connection on the handle and the spark point on the hande. Rest the metal on the connection and a few millimetre from the spark point and and pull the lever a few times (check no gas flows) to see if there is a spark. See video by clicking here: Check spark

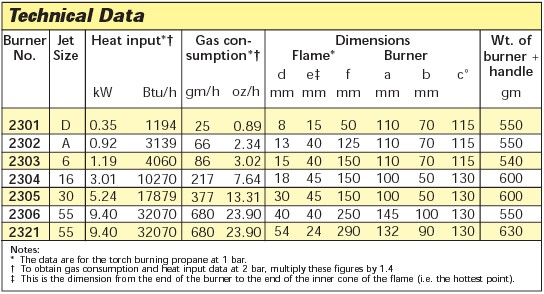

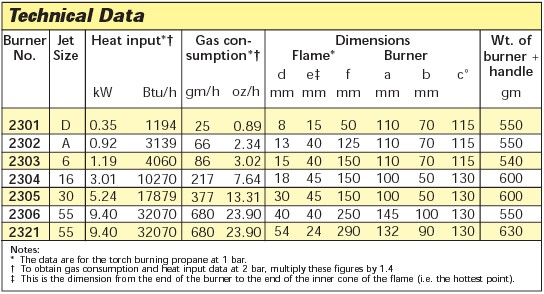

Technical Data - Autotorch 2300

These data are for the 2300 system burners but they are the same for the equivalent burners in the Autotorch System 2 - where for 2102 look at 2302, 2103 look at 2303 etc.

The 2301 and 2101 Burners are no longer available.

Technical Data - Autotorch System 2

These data are for the 2300 system burners but they are the same for the equivalent burners in the Autotorch System 2 - where for 2102 look at 2302, 2103 look at 2303 etc.

The 2301 and 2101 Burners are no longer available.

Technical Information - Autotorch 2

Gas supply for Autotorch 2100

For use at high pressure (0.35-2bar).

Cylinders

Any standard propane regulator with a screwed connection.

Any of the Tinyregs or Bijou regulators. The No.1051/11 variable Tinyreg for propane is recommended to give the best results from this torch.

Hose

Any of the Tinyregs or Bijou regulators. The No.1051 variable Tinyreg for propane is recommended to give the best results from these torches.

Hose

4.8mm high pressure hose to BS.3212/2 (no.1299) only must be used, with suitable hose clips.

Flashback Arrestors

Flashback arrestors are not needed for these torches

To check the spark

Turn off the gas using the valve with the screw down knob and disconnect the burner. Find a piece of metal to bridge the gap between the burner connection on the handle and the spark point on the hande. Rest the metal on the connection and a few millimetre from the spark point and and push the red button a few times to see if there is a spark. See video by clicking here: Check spark

Use of Torches

General uses of torches

Some of the uses of a Bullfinch torch are:

- Soft and silver soldering

- Central heating installation - capillary joints

- General plumbing work

- Factory maintenance work

- Public utility work

- Telecom work

- Electrical work

- Gas installation

- Tube bending

- Paint stripping

- Modelling

- Jewellery work

- DIY work

- Electrical work with soldering attachment

- Plastic tile laying

- Heat shrinking of sleeves and plastics - e.g. cable jointing for Telecom and electrical installations

- General household jobs

- Removal of fungal growth from beehives

- Other agricultural uses such as removal of feathers from bird carcasses

- Pottery kilns - see below

- Blacksmiths forges

- Glass bead making

- Bitumastic work

- Roof laying

- Torch-on roofing

- Weed burning

- Large pipe work - e.g. weld pre-heating

- Maintenance

- Jewellery

- Refrigeration

- Steam fittings installation

- Model engineering

- Heating and ventilating

- Agricultural machinery maintenance

- General engineering repair

- Appliance repair

- Lighting barbecues

- Lighting braziers, coal and coke fires

- Technoweld aluminium brazing

And for larger burners in Standard blowtorch range:

Uses of Autotorch brazing system

In addition to the uses shown which these brazing burners will usually do faster, the brazing system is ideal for silver soldering of copper pipes and as a portable bronze brazing system for the following areas of work:

The Autotorch acetylene system

Has improved performance over the Autotorch brazing system and is particularly good for Bronze brazing and Technoweld work.

Kilns

Bullfinch standard burners can be used for providing the burners for kilns. Most kilns have different requirements and so it is hard to give specific advice. We do have an informal information sheet on how our burners may be set up for a kiln - see downloads section. It is important to remember that the burners do require space round them to allow air to be drawn in for combustion at the front and the back of the burners.

Flame Temperatures

Technical information: flames

Although the flame temperature of an LPG (propane or butane) air burner at the hottest point is approximately 1900oC, the actual temperature a heated component can attain is much lower than this and depends on the burner, and the thermal properties of the component and its surroundings.

Acetylene-air and MAP//Pro gas-air will give flame temperatures 200-300oC above this and component temperatures 200-300oC higher too.

The Autotorch brazing burners can give temperatures up to 950oC under general conditions and up to 1200oC in ideal conditions only. They can therefore bronze braze under most conditions as well as being able to make faster soft and silver soldered joints. They are particularly good for hard/silver soldering of copper pipes.

The Autotorch 2300 series burners, the Autotorch System 2 burners and the Standard torch burners can give temperatures up to 800oC under general conditions. They are, therefore, ideal for soft and silver soldering and lead welding, but cannot be used for bronze brazing.

The Autotorch acetylene burners can give temperatures up to 1100oC undergeneral conditions and 1350oC under ideal conditions and can be used to do bronze brazing as well as the other general uses of torches discussed above.

MAP//Pro gas used on the FirePower, AutoPerformer and Performer torches will generally achieve temperatures between the Autotorch brazing burners and the Autotorch acetylene burners.

Sculpture Using Brazing Torch

The Scottish sculptor Sue White-Oakes has been using Bullfinch equipment (including the Autotorch Brazing System) for nearly 20 years in her innovative and beautiful work in copper. She was recently described as possibly the finest worker in metal outside Japan, and examination of her figurative sculptures shows why. Her work covers insects, crustaceans, fish, birds and mammals. It is applique sculpture, in which carefully crafted pieces of copper sheet are fitted together by brazing and soldering. Heat is needed to anneal the copper to make it malleable, to braze and solder, and to colour the final sculpture. For each of these operations, precise control over the heat source is required.

The Scottish sculptor Sue White-Oakes has been using Bullfinch equipment (including the Autotorch Brazing System) for nearly 20 years in her innovative and beautiful work in copper. She was recently described as possibly the finest worker in metal outside Japan, and examination of her figurative sculptures shows why. Her work covers insects, crustaceans, fish, birds and mammals. It is applique sculpture, in which carefully crafted pieces of copper sheet are fitted together by brazing and soldering. Heat is needed to anneal the copper to make it malleable, to braze and solder, and to colour the final sculpture. For each of these operations, precise control over the heat source is required.

The flexibility afforded by copper is shown in these two recent pieces: a Tawny Owl (60cm) and a Weaver Ant (30cm).

Courtesy of Sue White-Oakes 2009

Photos copyright Jim Pratt

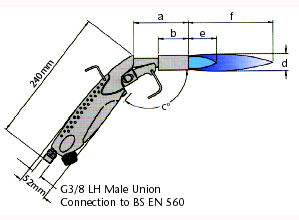

Technical Information - Autotorch Brazing Sys

Gas supply for Autotorch brazing system

The torch must be used with propane only at 4 bar pressure. We recommend the brazing regulator No.4041 which is already fitted to the kit.

Cylinders

Any standard propane cylinder.

Hose

4.8mm high pressure hose to BS.3212/2 (no.1299) only must be used, with suitable hose clips

Flashback arrestors

These are NOT required for Bullfinch propane-air torches.

To check the spark

Turn off the gas using the valve with the screw down knob and disconnect the burner. Find a piece of metal to bridge the gap between the burner connection on the handle and the spark point on the hande. Rest the metal on the connection and a few millimetre from the spark point and and push the red button a few times to see if there is a spark. See video by clicking here: Check spark

Technical Data - Autotorch Brazing

Technical Data for Autotorch Brazing System

The 4105 burner is noi longer available.

Flame Temperatures

Technical information: flames

Although the flame temperature of an LPG (propane or butane) air burner at the hottest point is approximately 1900oC, the actual temperature a heated component can attain is much lower than this and depends on the burner, and the thermal properties of the component and its surroundings.

Acetylene-air and MAP//Pro gas-air will give flame temperatures 200-300oC above this and component temperatures 200-300oC higher too.

The Autotorch brazing burners can give temperatures up to 950oC under general conditions and up to 1200oC in ideal conditions only. They can therefore bronze braze under most conditions as well as being able to make faster soft and silver soldered joints. They are particularly good for hard/silver soldering of copper pipes.

The Autotorch 2300 series burners, the Autotorch System 2 burners and the Standard torch burners can give temperatures up to 800oC under general conditions. They are, therefore, ideal for soft and silver soldering and lead welding, but cannot be used for bronze brazing.

The Autotorch acetylene burners can give temperatures up to 1100oC undergeneral conditions and 1350oC under ideal conditions and can be used to do bronze brazing as well as the other general uses of torches discussed above.

MAP//Pro gas used on the FirePower, AutoPerformer and Performer torches will generally achieve temperatures between the Autotorch brazing burners and the Autotorch acetylene burners.

Use of Torches

General uses of torches

Some of the uses of a Bullfinch torch are:

- Soft and silver soldering

- Central heating installation - capillary joints

- General plumbing work

- Factory maintenance work

- Public utility work

- Telecom work

- Electrical work

- Gas installation

- Tube bending

- Paint stripping

- Modelling

- Jewellery work

- DIY work

- Electrical work with soldering attachment

- Plastic tile laying

- Heat shrinking of sleeves and plastics - e.g. cable jointing for Telecom and electrical installations

- General household jobs

- Removal of fungal growth from beehives

- Other agricultural uses such as removal of feathers from bird carcasses

- Pottery kilns - see below

- Blacksmiths forges

- Bitumastic work

- Roof laying

- Torch-on roofing

- Weed burning

- Large pipe work - e.g. weld pre-heating

- Maintenance

- Jewellery

- Refrigeration

- Steam fittings installation

- Model engineering

- Heating and ventilating

- Agricultural machinery maintenance

- General engineering repair

- Appliance repair

- Lighting barbecues

- Lighting braziers, coal and coke fires

- Technoweld aluminium brazing

And for larger burners in Standard blowtorch range:

Uses of Autotorch brazing system

In addition to the uses shown which these brazing burners will usually do faster, the brazing system is ideal for silver soldering of copper pipes and as a portable bronze brazing system for the following areas of work:

The Autotorch acetylene system

Has improved performance over the Autotorch brazing system and is particularly good for Bronze brazing and Technoweld work.

Kilns

Bullfinch standard burners can be used for providing the burners for kilns. Most kilns have different requirements and so it is hard to give specific advice. We do have an informal information sheet on how our burners may be set up for a kiln - see downloads section. It is important to remember that the burners do require space round them to allow air to be drawn in for combustion at the front and the back of the burners.

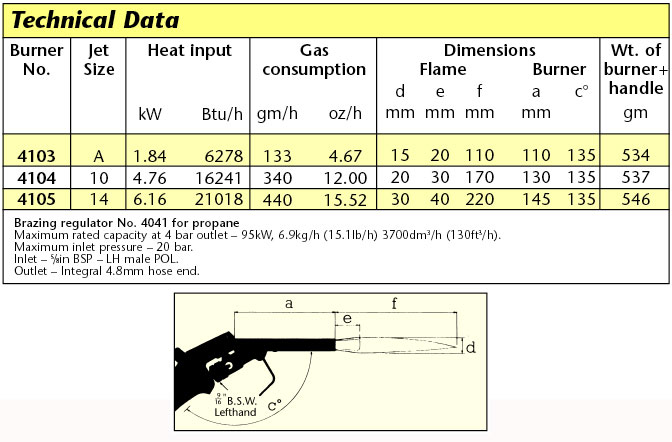

Technical Data - Performers

Flame Temperatures

Technical information: flames

Although the flame temperature of an LPG (propane or butane) air burner at the hottest point is approximately 1900oC, the actual temperature a heated component can attain is much lower than this and depends on the burner, and the thermal properties of the component and its surroundings.

Acetylene-air and MAP//Pro gas-air will give flame temperatures 200-300oC above this and component temperatures 200-300oC higher too.

The Autotorch brazing burners can give temperatures up to 950oC under general conditions and up to 1200oC in ideal conditions only. They can therefore bronze braze under most conditions as well as being able to make faster soft and silver soldered joints. They are particularly good for hard/silver soldering of copper pipes.

The Autotorch 2300 series burners, the Autotorch System 2 burners and the Standard torch burners can give temperatures up to 800oC under general conditions. They are, therefore, ideal for soft and silver soldering and lead welding, but cannot be used for bronze brazing.

The Autotorch acetylene burners can give temperatures up to 1100oC undergeneral conditions and 1350oC under ideal conditions and can be used to do bronze brazing as well as the other general uses of torches discussed above.

MAP//Pro gas used on the FirePower, AutoPerformer and Performer torches will generally achieve temperatures between the Autotorch brazing burners and the Autotorch acetylene burners.

Use of Torches

General uses of torches

Some of the uses of a Bullfinch torch are:

- Soft and silver soldering

- Central heating installation - capillary joints

- General plumbing work

- Factory maintenance work

- Public utility work

- Telecom work

- Electrical work

- Gas installation

- Tube bending

- Paint stripping

- Modelling

- Jewellery work

- DIY work

- Electrical work with soldering attachment

- Plastic tile laying

- Heat shrinking of sleeves and plastics - e.g. cable jointing for Telecom and electrical installations

- General household jobs

- Removal of fungal growth from beehives

- Other agricultural uses such as removal of feathers from bird carcasses

- Pottery kilns - see below

- Blacksmiths forges

- Bitumastic work

- Roof laying

- Torch-on roofing

- Weed burning

- Large pipe work - e.g. weld pre-heating

- Maintenance

- Jewellery

- Refrigeration

- Steam fittings installation

- Model engineering

- Heating and ventilating

- Agricultural machinery maintenance

- General engineering repair

- Appliance repair

- Lighting barbecues

- Lighting braziers, coal and coke fires

- Technoweld aluminium brazing

And for larger burners in Standard blowtorch range:

Uses of Autotorch brazing system

In addition to the uses shown which these brazing burners will usually do faster, the brazing system is ideal for silver soldering of copper pipes and as a portable bronze brazing system for the following areas of work:

The Autotorch acetylene system

Has improved performance over the Autotorch brazing system and is particularly good for Bronze brazing and Technoweld work.

Kilns

Bullfinch standard burners can be used for providing the burners for kilns. Most kilns have different requirements and so it is hard to give specific advice. We do have an informal information sheet on how our burners may be set up for a kiln - see downloads section. It is important to remember that the burners do require space round them to allow air to be drawn in for combustion at the front and the back of the burners.

Technical Information - Radiant Heaters

Gas supply for radiant heaters

The 2200 heaters are ready for use and are fitted with 2m of 8mm bore high pressure hose to BS.3212/2 (Bullfinch No.1319) and with a low pressure regulator for propane with an output of 37mbar (Bullfinch No. 330). The regulator can be fitted to any standard propane cylinder with a 5/8in BSP - LH POL female outlet. We recommend high pressure hose since it will withstand wear much better than low pressure tubing.

Technical data: Master blp propane gas heaters

Technical Information - Master heaters

Gas heaters (BLP11, BLP17, BLP33, BLP53, BLP73, BLP103)

These high quality heaters, provide safe, reliable heat.

They are fully approved and tested to European standards.

They come complete with hose and regulator for the standard 5/8in BSP POL fitting on most propane cylinders.

These gas heaters have an electrical lead provided. The BLP11 and BLP17 are for 240V and have a three pin plug attached. For the BLP33, BLP53 and BLP73 - you need to provide a plug for 230V or 110V supply - these are dual voltage heaters - you will need to select which you require.

All you need to provide is:

- an electrical supply (and electric plug for the MP heaters and larger REM heaters)

- a cylinder(s) of propane

At least one 47kg cylinder is required for the heaters, and for continuous use for larger heaters on colder days it would be better to provide two cylinders joined by an extra pigtail (Bullfinch 1494) and Y manifold (Bullfinch 1506).

You get a long heating time between refuelling by linking cylinders together.

Technical Information - Industrial Heating

Gas supply for Industrial heating

All these appliances require a cylinder of gas, hose, hose clips and a regulator. All appliances should be used with 4.8mm high pressure hose (No. 1299) apart from No. 1380 which can be used with 8mm low pressure tubing (No. 1314) or 8mm high pressure hose (No. 1319). Suitable hose clips must also be used.

Technical Data - Industrial Heating

Gas Supply Information - Low Pressure Appliances

Low pressure appliances - Type I3+ - requirements for gas supply

Where type I3+ low pressure appliances are referred to (butane at 28/29mbar or propane at 37 mbar), the following hoses, clips and regulators are suitable:

- Regulator

- No. 7026 for a butane cylinder with a 20mm clip on connection - 28 mbar or

- No. 7027 for a butane cylinder with a 21mm clip on connection - 28 mbar or

- No. 330 for a propane cylinder with a POL connection - 37 mbar or

- No. 7069 for a propane cylinder with a 27mm clip on connection - 37 mbar (eg Calor Patio Gas, or Flogas Leisure Propane Gas)

- Hose

- No. 1314 or No.1319 - Hose - we would suggest at least 3m of 8mm bore hose

- Hose Clips

- No. 1306 Hose clips - 2 off

These products can also generally be used off a I3B/P supply which is propane or butane at 30mbar pressure. This is the supply in new caravans and in some other environments and means that they can be used from a Gas/Barbecue point - our No. 6087/01.

Always check the manufacturers' instructions before using any appliance.

Gas Supply Information - Low Pressure Appliances

Low pressure appliances - Type I3+ - requirements for gas supply

Where type I3+ low pressure appliances are referred to (butane at 28/29mbar or propane at 37 mbar), the following hoses, clips and regulators are suitable:

- Regulator

- No. 7026 for a butane cylinder with a 20mm clip on connection - 28 mbar or

- No. 7027 for a butane cylinder with a 21mm clip on connection - 28 mbar or

- No. 330 for a propane cylinder with a POL connection - 37 mbar or

- No. 7069 for a propane cylinder with a 27mm clip on connection - 37 mbar (eg Calor Patio Gas, or Flogas Leisure Propane Gas)

- Hose

- No. 1314 or No.1319 - Hose - we would suggest at least 3m of 8mm bore hose

- Hose Clips

- No. 1306 Hose clips - 2 off

These products can also generally be used off a I3B/P supply which is propane or butane at 30mbar pressure. This is the supply in new caravans and in some other environments and means that they can be used from a Gas/Barbecue point - our No. 6087/01.

Always check the manufacturers' instructions before using any appliance.

Safety Checks - Hose/regulator life

Safety Checks

With regard to safety checks for our equipment we would recommend a comprehensive check as follows when the equipment has not been used for sometime and regular checks as follows:

- regularly check by smell and leak detecting fluid that there are no leaks of gas

- regularly check that the appliance is working correctly and the flames are burning correctly (usually an almost colourless blue flame) and there are no signs of overheating in the appliance or damage to the appliance

- regularly check that any lpg hose is clean and free from undue wear and cracking and is properly attached to the regulator and the appliance with hose clips or ferrules

- when replacing the gas cylinder ensure that the new cylinder has a clean and undamaged connection and the regulator connection is clean and undamaged

- please consult the instructions for the appliance for more specific checks and instructions - these can be obtained online for most appliances

- the Bullfinch Safety Precautions give guidance for the use of many lpg appliances

- the equipment should not be used if you are concerned over any of these aspects. Please then consult your dealer or manufacturer

Hose Life

With regard to hose life we issue the following recommendation:

Our hose is made in accordance with BS3212/2.

Storage - see BS ISO 2230. Hose generally has a shelf life of 7 years as long as it is stored at reasonable temperatures in dry conditions away from direct sunlight. This life can be extended by another 3 years if it is examined and tested and proved to be in good condition.

Service life - From the date the hose is first used we would recommend it is replaced after a further 5 years and that it is examined regularly for signs of cracks or wear or gas leakage and is replaced if it is not in good condition. Generally discolouration due to sunlight is not harmful as long as there are no signs of cracking.

Regulator Life

Conformity to Regulations and CE Marking

Gas Appliances Regulations 2018

It is a legal requirement that many gas appliances offered for sale conform to the Gas Appliances Regulations 2018 (which come from the European Gas Appliances Regulations EU 2016/426). These are generally appliances that are used to heat people, cook or provide lighting. They have to be independently certified by ‘Notified Bodies’ and have to carry the CE mark to show that they conform to the regulations. In addition a Notified body has to carry out surveillance of the production of these appliances.

The Bullfinch brand appliances certified are: Radiant heater No. 2200, Industrial space heater No. 1400, and other products certified are Cabinet heaters 7098, 7099, and Marquee heaters 2208 and 2217 and Master Heaters, and boiling rings etc. All other Bullfinch brand appliances and equipment are exempt.

Blowtorches, furnaces and Decorative flame appliances such as Event torches, beacons etc do not fall under the Regulations and are not required to be CE marked.

Essential requirements We take safety and performance of appliances very seriously and where Gas Appliances doe not require CE marking they conform to the Essential Requirements of these regulations and other European and applicable standards. They also meet the essential requirements of the Pressure Equipment Regulations - see below.

Construction Products Regulations 2011

None of our products come under these regulations and so do not need to be CE marked for them - many are CE marked under the Gas Appliances Regulations - see above.

Pressure Equipment Regulations 2016

Products operating on gas pressures above 0.5 bar are required to meet these regulations. In the case of appliances made and sold by Bullfinch this means they have to meet sound engineering practices and we can make a declaration that they do.

Flashback arrestors

Please note that Flashback arrestors are not needed when propane or butane is used with air. This is true for Bullfinch propane or butane burning appliances. Flashback arrestors are required for the Bullfinch Autotorch for acetylene and for oxy-propane and oxy-acetylene systems.

Download letter from HSE for verification

COSHH and RoHS and REACH

Our products conform to these regulations and we require our suppliers to ensure that their products conform to them

Conflict Free Minerals Policy

BULLFINCH GAS EQUIPMENT LTD will not knowingly procure material supplies and components that contain minerals that directly or indirectly finance or benefit armed groups in the Democratic Republic of Congo (DRC) or an adjoining country. We stipulate that our suppliers must support this policy in their own procurement guidelines for their supply chain.

Modern Slavery Act 2015

BULLFINCH GAS EQUIPMENT LTD comply with the provisions of this act to prevent the use of slavery, servitude and forced or compulsory labour and human trafficking in our workforce. We stipulate that our suppliers must conform to this act and ensure that those in their supply chain also conform to the act.

Low Pressure Appliances

Traditionally most low pressure appliances in UK operate at 28/29 mbar with butane and 37 mbar with propane. This is category I3+. General portable appliances like patio heaters, barbecues, boiling rings, hotplates will operate off either supply but care needs to be taken to read the instructions as there may be some variation in this.

New caravans and some other environments now have to be supplied with special regulators that are rated at 30mbar whether propane or butane is used. This is category I3B/P. Built in appliances will be made for this pressure and they may not work satisfactorily on a I3+ supply. Portable appliances will generally work satisfactorily off this supply for example using our Gas/barbecue point no. 6087/01.

Gas Supply Information

Low pressure appliances - Type I3+ - requirements for gas supply. Where type I3+ low pressure appliances are referred to (butane at 28/29mbar or propane at 37 mbar), the following hoses, clips and regulators are suitable:

- Regulator

- No. 7026 for a butane cylinder with a 20mm clip on connection - 28 mbar or

- No. 7027 for a butane cylinder with a 21mm clip on connection - 28 mbar or

- No. 330 for a propane cylinder with a POL connection - 37 mbar or

- No. 7069 for a propane cylinder with a 27mm clip on connection - 37 mbar (eg Calor Patio Gas, or Flogas Leisure Propane Gas)

- No. 1314 or No.1319 - Hose - we would suggest at least 3m of 8mm bore hose

- No. 1306 Hose clips - 2 off

These products can also generally be used off a I3B/P supply which is propane or butane at 30mbar pressure. This is the supply in new caravans and in some other environments and means that they can be used from a Gas/Barbecue point - our No. 6087/01.

Always check the manufacturers' instructions before using any appliance.

LP Gas and Equipment association

Member of Liquid Gas UK (previously UKLPG, LPGA and ALGED) where you can get technical and safety advice.

There is a comprehensive set of industry recognised Codes of Practice available.

For information on LPG Applications see:

Exceptional Energy in Action - the LPG Applications Website www.lpg-apps.org

Flash Back Arrestors

Flashback arrestors

Please note that Flashback arrestors are not needed when propane or butane is used with air. This is true for Bullfinch propane or butane burning appliances. Flashback arrestors are required for the Bullfinch Autotorch for acetylene and for oxy-propane and oxy-acetylene systems.

Download email from HSE for verification

.

Safety Information Leaflet

Gives much of the information in this section on one leaflet. Ideal for all users of LPG - dealers, customers, users, students etc. Contact us for copies or you can download in 2 parts.

Safety Leaflet Part 1 (PDF) | Safety Leaflet Part 2 (PDF)

Public/Products/Employers Liability Insurance

We carry £10 million of public and products liability and employers liability insurance

Expires - 30th June 2026

Quality Management System

Bullfinch systems controlling quality have been certified as meeting the International Quality Standard BS EN ISO 9001:2015.

Download Certificate

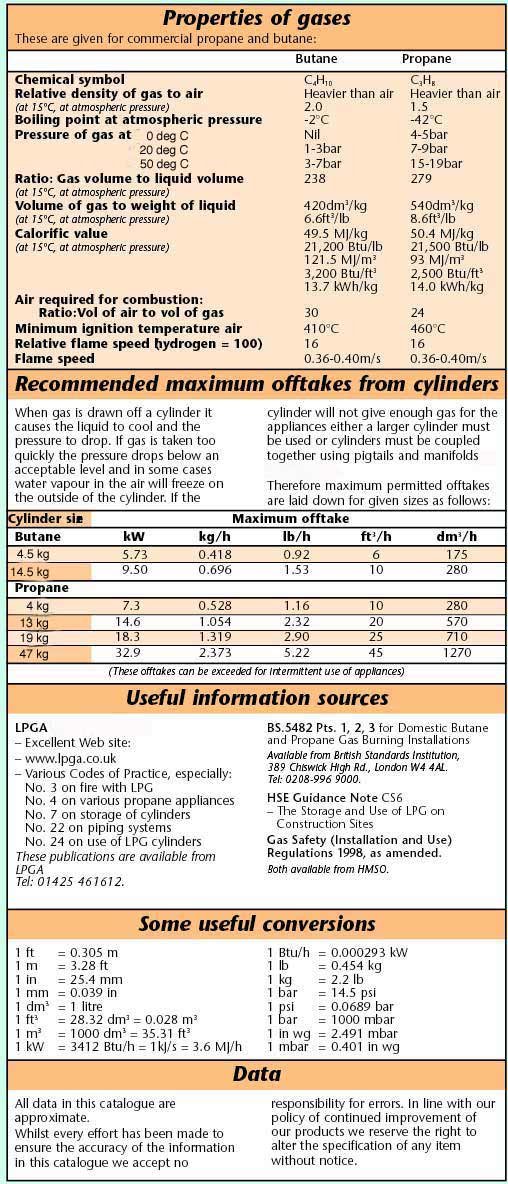

Properties of gases and other information

Safety Precautions & Ventilation Requirements

Bullfinch appliances and equipment have all been especially designed for use with Liquefied Petroleum Gases (propane and butane) and will give long and reliable service to the user provided they are correctly operated and maintained.

It is, however, essential that sensible safety precautions be followed with any appliances using butane and propane gases which are considerably heavier than air and highly inflammable; and because of these facts, we list here simple safety measures which should always be adopted when using the appliances. Failure to observe these could result in a serious accident.

Personnel

Ensure that you know how to operate the equipment and never allow anyone other than a competent person to connect or disconnect appliances and regulators.

Appliances

Read the instructions provided with the appliance, taking particular care to ensure that the gas type is correct and the supply can provide sufficient gas for the appliance and any other appliances drawing on the same supply. Ensure that the regulator provides gas at the correct pressure. Site the appliance so that it cannot overheat any surfaces and cannot cause an accident. The appliance should burn cleanly without the formation of soot. If it does not, turn it off and ensure the maintenance is carried out by a competent person before re-using.

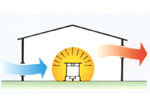

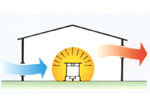

VentilationAll LPG equipment consumes oxygen and emits carbon dioxide in use so that when using unflued equipment in a confined space it is important that there is ADEQUATE PERMANENT VENTILATION & ADEQUATE FREE SPACE surrounding it. These requirements are laid down in various British Standard Codes of Practice and a summary of the main requirements is given below. |

|

CylindersMake sure the cylinder is large enough for your requirements. Cylinders must be sited away from any heat source, in a well ventilated place wherever possible and must stand in a stable upright position. Never put a cylinder in a sewer, culvert or work hole. Propane cylinders should not be stored indoors. Don’t use Propane cylinders indoors except when necessary for work processes and/or for short |

|

RegulatorsBullfinch appliances should only be used in conjunction with a British Standard regulator. It is important to check that the regulator; a) gives the correct pressure for the appliance, b) is suitable for the gas being used (check also that the gas is suitable for the appliance), c) has a large enough maximum flow for the appliance. For propane cylinders, and for butane cylinders having screwed connectors: Always, before connecting a regulator to a cylinder, ensure that the mating parts are clean, free from dirt and undamaged, and, in the case of butane regulators, check that the washer is in place on the spigot of the connector and is in good condition. The connecting nut of the regulator must be spanner tightened to the cylinder valve. (Note: The thread is left-handed.) For butane cylinders with ‘switch-on’ or ‘clip-on’ connectors: Consult your dealer on the type of adaptor or regulator you require and fit in accordance with the manufacturer’s instructions. |

|

Screwed connectionsMost screwed connections should be firmly tightened with a spanner. Note that all nuts with notches on the hexagon have a left-handed thread. |

|

Hose and clipsBritish Standard hose only must be used for passing these gases and it must be securely attached with hose clips to the ends provided. Low pressure hose, (which must show the number BS.3212/1) must only be used for pressures up to 50mbar. High pressure hose (which must show the number BS.3212/2) can be used for all pressure up to 17.5 bar. Hose and clips should be regularly inspected and replaced if worn or damaged. |

|

LeaksAfter connecting appliances/regulators, etc., check that there is no leak of gas before using. Propane and butane have a distinctive smell and a leak can usually be detected immediately by this fact. If a leak is suspected, extinguish all naked lights and close the cylinder valve. NEVER look for a leak with a naked flame, but trace it by smell and confirm by brushing leak-detecting fluid (or soapy water) over the suspected joint. Equipment must not be used until any leak is eliminated. |

|

FireIf a fire develops, try to turn off the cylinder valve, remove the cylinder from the fire and extinguish the fire with a dry compound extinguisher. (Do not use a water jet on a fire of liquid LPG). If this is too dangerous call the fire brigade and move all people from the area. |

|

Turning offAfter using a portable appliance it is IMPORTANT a) that the cylinder valve is closed first thus allowing the gas in the system to burn off: b) that any valve fitted to the appliance is then closed to ensure that when the appliance is again used the turning on of the cylinder valve does not allow gas to escape from the appliance before being lighted. |

|

ProblemsIf you are in any doubt about the operation of the appliance please consult your dealer, or contact us directly. |

|

Ventilation Requirements

For the use of unflued appliances in a confined space. These are general requirements - those for specific appliances may vary from these - see appliance instructions.

Main requirements

- The volume of the room space in which an appliance is used must be at least 10m3 for each 1kW of continuous heat input with a minimum room size of 15m3. This is in addition to the volume required for other appliances.

- Permanent ventilation must be provided by at least 25cm2 of free ventilation area for each kW of continuous heat input. This is in addition to that required for other appliances and the occupants, and there must be a minimum of 50cm2 of free ventilation area. The ventilation area must be divided between high and low level, and the ventilators must be constructed so that they cannot be closed. If the space is to be used for sleeping, the appliances must be turned off before retiring.

Gases - Technical Information

LPG - liquefied petroleum gas

Sold commercially as propane and butane - is hydrocarbon gas that forms a liquid at normal temperatures when pressure is applied to it, and the pressure inside the cylinder is 7-8 bar for propane and 1-2 bar for butane at normal temperatures. When the cylinder valve is opened, gas flows out at these pressures and some of the liquid turns to gas to replace it. However, these pressures are usually too high to be fed directly to appliances and so a regulator has to be fitted to reduce and control the pressure.

Most Bullfinch appliances operate at high pressures (ie in the range 0.35 to 2 bar) since this gives the hot compact flames required for torches, lights and portable heating equipment. The Autotorch brazing system operates at a higher pressure of 4 bar to achieve the higher temperatures for bronze brazing. The fact that the equipment requires one cylinder of gas only containing very high quantities of energy, makes the Bullfinch range ideal for providing heat and light sources that are portable and can be used where other energy supplies are not readily available. The Superglow heaters and most domestic equipment operate at ‘low pressure’ (ie well below 1 bar).

Butane or propane?

Similarities

Both gases burn clearly and have a high calorific value, giving similar flame shapes and heat outputs, and in principle, appliances will burn equally well off either gas.

Differences

However, as gas is drawn off from the cylinder and liquid turns back into gas, the liquid cools down causing the rate of change from liquid to gas to slow down. This effect is particularly marked for butane which will not turn from liquid to a gas below 0oC, so that on cold days or when the gas is being withdrawn at a high rate, the liquid gets so cold that it delivers very low amounts of gas, or indeed no gas at all. Thus butane tends to be used for low pressure domestic appliances indoors, or outdoors in the summer only. Propane continues to turn from liquid to gas at much low temperatures than butane and thus gives a high pressure of gas on the coldest of days. Although propane cylinders can be used indoors on a temporary basis, they should not be stored indoors because of the higher pressures in them.

Thus we recommend propane for our appliances, though butane can be satisfactorily used in many instances.

Flame Temperatures

Technical information: flames

Although the flame temperature of an LPG (propane or butane) air burner at the hottest point is approximately 1900oC, the actual temperature a heated component can attain is much lower than this and depends on the burner, and the thermal properties of the component and its surroundings.

Acetylene-air and MAP//Pro gas-air will give flame temperatures 200-300oC above this and component temperatures 200-300oC higher too.

The Autotorch brazing burners can give temperatures up to 950oC under general conditions and up to 1200oC in ideal conditions only. They can therefore bronze braze under most conditions as well as being able to make faster soft and silver soldered joints. They are particularly good for hard/silver soldering of copper pipes.

The Autotorch 2300 series burners, the Autotorch System 2 burners and the Standard torch burners can give temperatures up to 800oC under general conditions. They are, therefore, ideal for soft and silver soldering and lead welding, but cannot be used for bronze brazing.

The Autotorch acetylene burners can give temperatures up to 1100oC undergeneral conditions and 1350oC under ideal conditions and can be used to do bronze brazing as well as the other general uses of torches discussed above.

MAP//Pro gas used on the FirePower, AutoPerformer and Performer torches will generally achieve temperatures between the Autotorch brazing burners and the Autotorch acetylene burners.